The Bioserver

A mobile, modular, and scalable biomass energy solution

What is a Bioserver?

VGrid’s Bioserver generates clean, consistent, and sustainable electricity from agricultural and forestry waste. In the process, high-quality biochar and bio-liquids are produced.

When added to plants and soil, these co-products have been shown to significantly increase crop yields while reducing water and fertilizer.

Benefits:

Consistent, Sustainable Energy | Valuable Co-Benefits

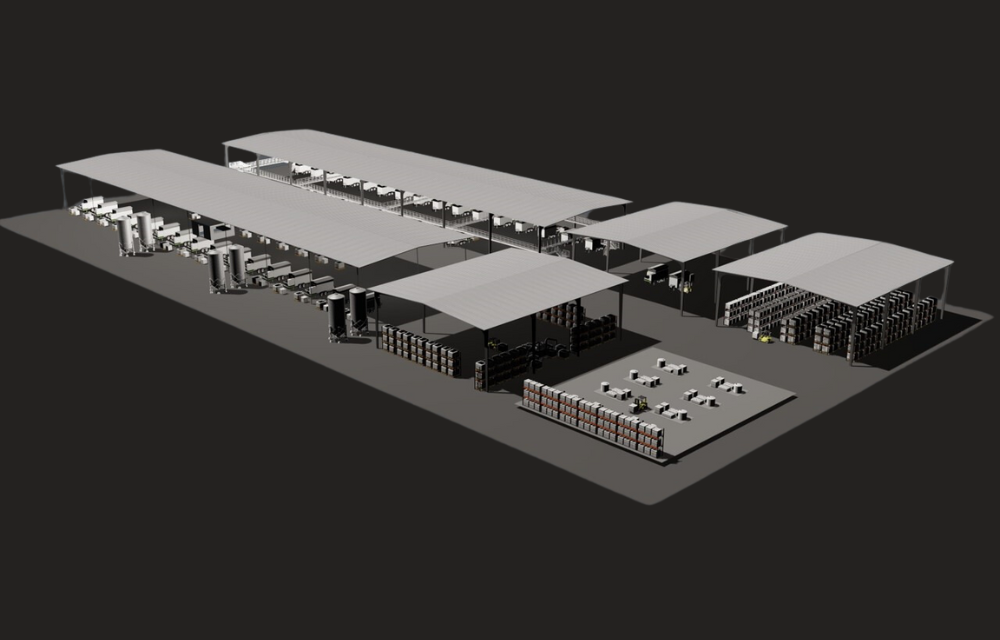

Mobile, Modular, Flexible, and Highly Scalable.

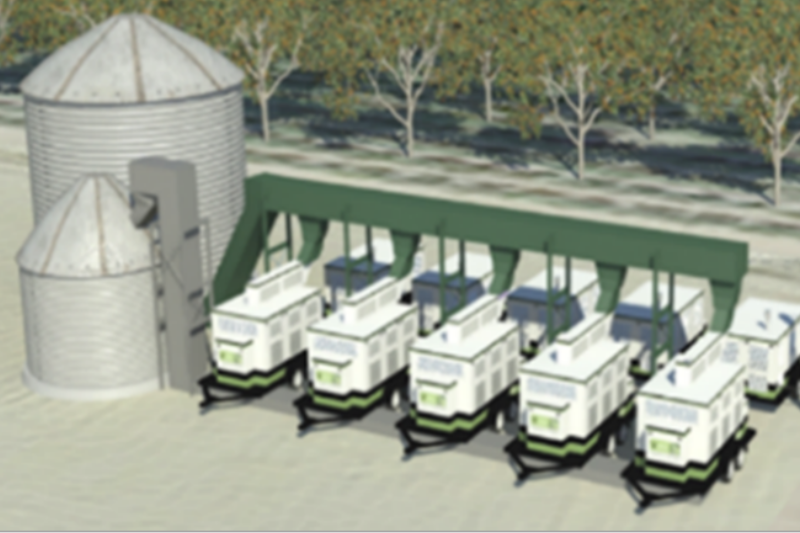

Bioservers deploy locally where the biomass is located rather than transporting it over long distances to a central facility. This enables a more efficient and profitable model with a lower overall carbon footprint.

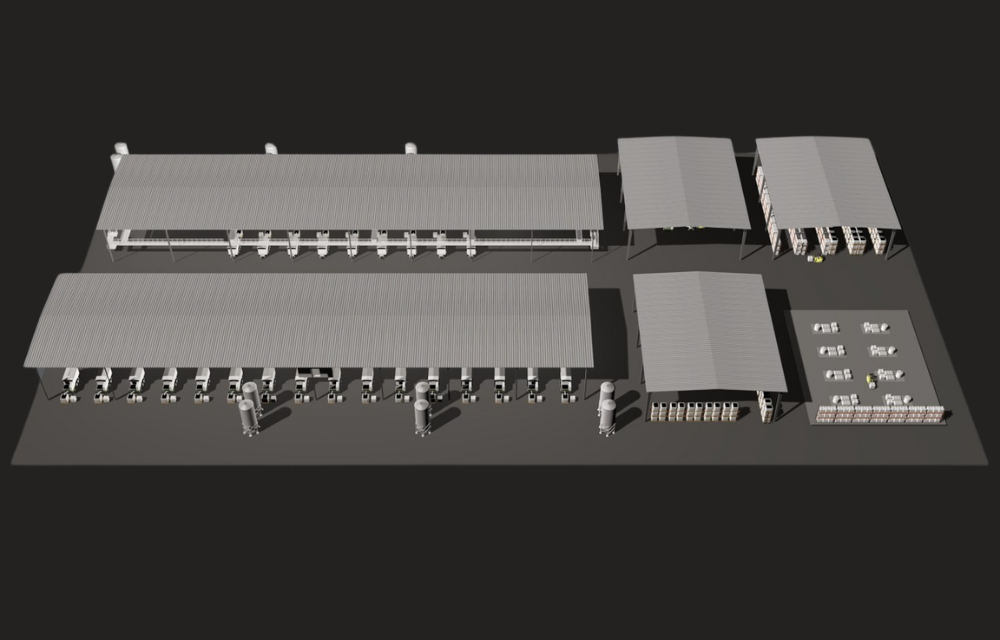

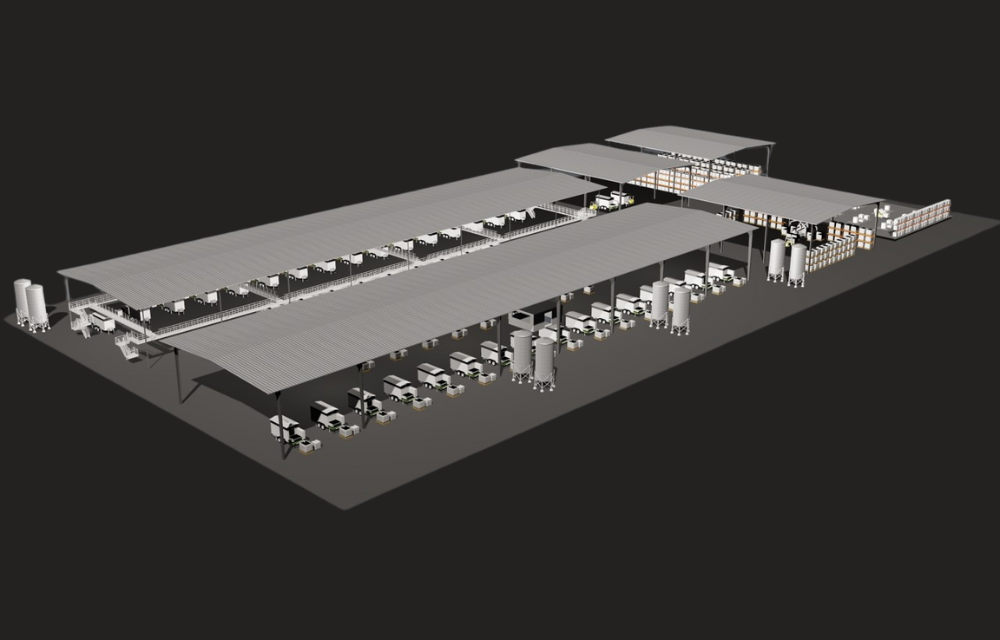

VGrid’s modular “plug and play” approach enables Bioserver arrays of any size, providing the flexibility to scale quickly according to the available biomass and the local market demand for co-products.

Benefits:

Modular | Efficient | Scalable

Tapping into the natural carbon cycle.

Instead of allowing biomass to decompose and release CO2 back into the atmosphere, VGrid’s biochar captures and stabilizes the carbon for over a thousand years, helping to reverse climate change.

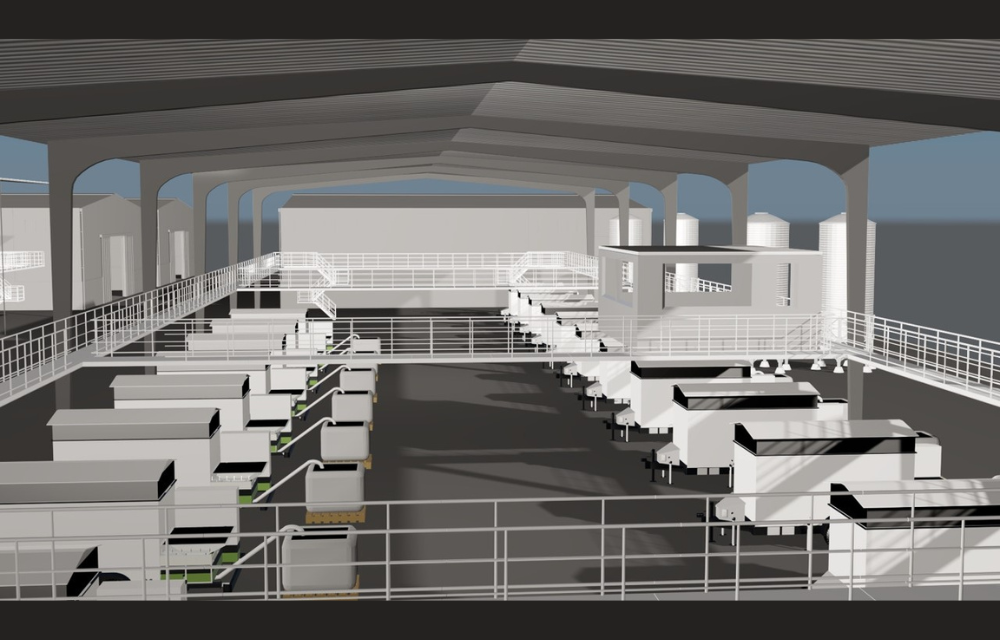

The Bioserver consists of two trailer-based units.

Biomass Gasification Unit

The Bioserver employs a low-oxygen, high-temperature downdraft gasifier that is part of a system of filtering and condensing units designed to create and clean syn gas for the gen set.

Twin-Engine Generator Set

Bioelectricity is created through two Ford 6.8 Liter V10 engines, modified to run entirely on the syn gas produced by the gasifier unit. Electricity can be consumed onsite or uploaded onto the power grid.

Approved for grid interconnection.

VGrid’s Bioserver produces clean and renewable bioelectricity, biochar, and bioliquids.

Current Operations:

Visalia, California, U.S.A

VGrid’s primary production site is located at South Corner Dairy in Visalia, California, where the Bioservers are providing electricity to help power the dairy’s operations. Excess bioelectricity is put back onto the California power grid.

The first generation Bioservers were first installed in 2019. These units were upgraded to Model M100 Bioservers in 2021. With the introduction of the Model M200 Bioserver in 2022, VGrid is now transitioning each machine to the latest technology.

Bioserver emissions are below the San Joaquin Valley Air Pollution Control District (SJVAPCD) Best Available Control Technology (BACT) thresholds (e.g., 2 pounds/day for NOx, SOx, VOC, PM10, and PM2.5) per device. The Bioserver engines include a 3-way catalyst to control NOx, CO, and VOC emissions and meet the SJVAPCD requirements for syngas-fueled engines

With a five year performance history, the Bioserver has proven its reliability, scalability, production capacities, and overall value.

Partner With Us.

Mobile, modular, and scalable technology that produces sustainable electricity, sequesters CO2 at scale, and maximizes ‘waste-to-value’ overall.